Top 10 Nanotechnology Innovations

UPDATED LIST: For the top nanotechnology innovations since 2020, view Top 10 new nanotechnology innovations

The top nanotechnology innovations that feature in this article are the ten most viewed nanotechnologies published on IN-PART between 2014 and 2017. By taking this view, we see these innovations to be an indicator of the technical systems and applications of nanotechnology that are most appealing to our community of R&D professionals.

Each of these innovations has been published by a research institute on IN-PART’s matchmaking platform for university-industry collaboration with a view to finding external partners for co-development and commercialisation. After creating a free account, through the links below you can read the full, non-confidential, article. If the opportunity is relevant to your research interests, you can submit technical questions or a request for an informal introduction to the university.

1. Printing customised cross-regional properties

The idea of printing 3-dimensional objects, at first, seemed futuristic. It was mostly a novelty. But now, 3D-printing is a game-changing technology with applications in everything from machine components to printing organs. However, a major issue for 3D-printing is the low strength and brittleness of the resulting structures…

A team of researchers in the USA are tackling this problem by reinforcing 3D-printed structures on the nanoscale. By using magnetics, they can align printed particles in controlled and varying orientations. This not only makes structures more stable, it also offers the ability to vary properties across regions within a single material. For example, having one part bendy and the other stiff. The researchers are currently looking for external partners to help develop their technology for applications in the biomedical, engineering, and electrical industries.

Unfortunately, this technology is no longer available for collaboration, but there is a similar innovation on IN-PART from researchers at University of California, Santa Barbara: A Process for Rapid, Continuous 3D Printing.

2. Russian doll nano-emulsions

Emulsions, mixes of immiscible liquids such as oil and water, are found in products that range from pharmaceuticals and pesticides to make-up and mayonnaise. ‘Multi-emulsions’, multi-layered matryoshka doll style, oil-in-water-in-oil systems have seen growing interest from academics in recent years. However, current methods work only on large-scales and produce single multi-emulsions at slow rates.

Now, academics from the US West Coast have developed a process to solve some of the problem incolved in creating multi-emulsions. Their technology uses sequential, high-energy emulsification to create nanometre-sized droplets of oil, suspended in water droplets, which are in turn suspended in a second oil. This innovation opens the door for products such as novel encapsulated drugs and pesticides, or even for ultra-low-fat salad dressings.

Keen to learn more? Read the full article.

3. Tiny scales with massive impact

‘Film Bulk Acoustic Resonators’ (FBARs) can detect a change in mass at extremely small scales – small enough to pick up the presence of a virus weighing a single femtogram (1×10-18kg)! These highly accurate sensors have varied applications – from measuring VOCs as a monitor of air quality, to detecting biomarkers for cancers (and other diseases), and even in the detection of explosives. Measuring mass at such tiny scales requires a novel approach. Film Bulk Acoustic Resonators use changes in the resonant frequencies of acoustic waves to detect mass fluctuations. Although super accurate, liquids (which supress resonance) and variable temperatures (which alter frequencies) both play havoc with their accuracy.

But fear not, researchers at a world-leading UK university have designed a novel FBAR innovation that can be tailored to cope under different temperatures and liquid mediums. It’s hoped that this development will make the technology a viable commercial option, and the researchers are looking for external collaborators for further development and market application.

Unfortunately, this technology is no longer available for collaboration, but there is a similar innovation on IN-PART from researchers at Columbia University: High-Performance RF Filter Arrays Fabricated Directly onto CMOS Circuitry.

4. Ditching the feather duster

The efficiency of solar cells, air conditioners, cooling coils, and many other types of energy-intensive equipment is dependent upon the cleanliness of their heat-transfer surfaces. One study has estimated that solar energy output losses from dust could be as much as 25%! Self-driving brooms seem like a smart solution, but they require charged batteries and can only cover so much ground (the world’s largest solar farms cover thousands of acres!)

As a solution to dusty inefficiencies, academics at a Sunshine State university have developed a water-resistant coating that reduces dust adhesion to surfaces by 95%. In the form of a nanoparticle suspension, it can be applied using a variety of methods or incorporated into other coatings, and bonds with steel, glass and plastic. The academics are open to enquiries for specific applications.

Unfortunately, this technology is no longer available for collaboration, but there is a similar innovation on IN-PART from researchers at Monash University: Smart Surface Coating.

5. Harvesting nano-mechanical human energy

Battery life is a critical issue for embedded monitoring technologies (e.g. pacemakers, engine feedback, and pipeline monitoring). But by harvesting mechanical energy from moving parts (e.g. humans), it’s possible to extend the lifespan of embedded monitoring devices. The problem with current harvesters, however, is that they are limited by their ability to absorb energy at mechanicals frequencies exceeding 100 Hz.

The latest advance in this field comes from researchers connected to a regional SATT in France, who have developed a new harvester that uses electrostatics to capture energy at lower, human-generated frequencies. This technology is in development and close to achieving a conversion efficiency near the theoretical limit of 10 microW per device. An international patent has been filed and the researchers are keen to engage with industry about deploying their innovation for specific applications.

Unfortunately, this technology is no longer available for collaboration, but there is a similar innovation on IN-PART from researchers at the University of Utah: Motion Based Energy Harvester for Wearables.

6. Graphene-enhanced nanoelectromechanical systems

As the adoption of tiny machines becomes widespread in diverse markets from healthcare to defence, the next logical step is further miniaturization. Nanoelectromechanical systems (NEMS) show great promise in many applications such as ultrasensitive sensors and components for radio frequency communication systems. But so far, their performance has been limited due to the use of heavy and thick metal electrodes that dampen the vibration of resonators.

To overcome this issue, academics in the USA have developed nano-resonators that utilise graphene as an ultra-thin, ultra-light electrode. The researchers have observed a striking increase in device performance, including greater detection speeds, higher sensitivity and greater limits of detection. The team is looking to engage in conversation with businesses around licensing and/or co-developing their technology.

Find out more in the full technology article.

7. A final coating

Nano-structured coatings are a great way of adding new surface properties to a product without changing the base materials. Nanocoatings can be applied to an object to dramatically improve functionality – for example, hydrophobic glass upon which raindrops bounce straight off; slippery, hydrophilic medical devices that can be inserted with minimal discomfort; or coatings with highly-antibacterial properties. These specialised coatings are often applied through harsh processes during manufacturing, making it difficult to reapply them to finished products, also limiting what materials can be used in the process.

To overcome these limitations, a team of academics from Australia have developed several new methods to apply nanocoating films. In one of these techniques, flexible, multi-layered nano-films can be built and then transferred using a high-strength adhesive layer. Another technique from the same researchers allows a nanocoating to be applied to any surface in a series of two quick spray-on coats. These new coatings enable greater flexibility, easy removal and reapplication.

Looking for more information? It’s covered in the full technology article.

8. A coat of arms against implant infections

Implanted medical devices save thousands of lives each year. However, with these implants comes a high-risk of infection. The surfaces of implanted devices can be an ideal home for bacteria. Infections from medical devices pose a serious problem, with over a million people infected each year in the US – increasing hospital stays by two weeks and mortality rates by 25%.

In the search for a solution, academics in the UK are developing completely “non-stick” nanocomposite coatings that employs electrostatic repulsion to prevent bacteria from settling their roots to a surface. In trials, when these coatings were applied, the researchers found that infection rates dropped by 98%. The team are looking to increase the efficacy of their nanocomposites and are seeking a commercial partner for collaboration.

Interesting in learning more? Click through to the full article.

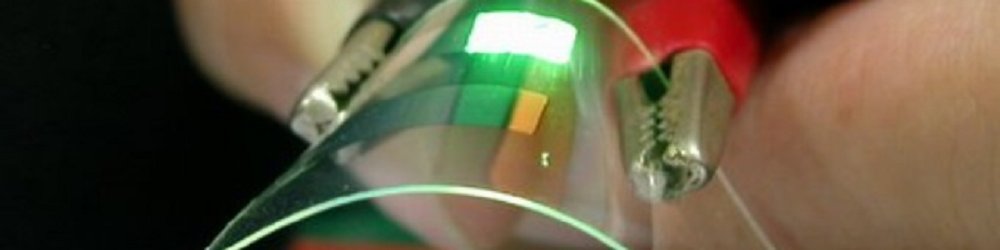

9. Transparent conducting flexible thin films

From integrated sensors that track our every move, to AI-driven personal assistants and SLR-quality cameras, it’s hard to imagine where smartphone manufacturers will go next. Facebook’s Oculus team is betting that our addictive little devices will morph into portals for augmented reality, while Samsung’s iris scanner takes cybersecurity far beyond the now-ubiquitous fingerprint scan. Well, how about being able to roll up your phone up to tuck away in your pocket?

Some smartphone manufacturers have already started developing flexible devices, but their current iterations are clunky and more novel than necessary. In a move that could revolutionise flexible electronics for our smartphones and beyond, researchers at a world-leading UK university have developed a new method to manufacture highly-conductive thin films with transparent conducting oxide nanoparticles. Their techniques operate at much lower processing temperatures, which in turn will allow manufacturers to use more suitable temperature-sensitive substrates – such as flexible plastics with enhanced electrical properties. The team are on the look-out for collaborators.

Flex your innovation muscles and read the full article.

10. Printing everyday safety on the nanoscale

Cellular silicon foams save lives every single day. Found in items all around us, these porous materials can absorb huge amounts of energy to reduce impact on the human body during car accidents, football matches and workplace incidents. But this workhorse of safety equipment has its limitations. For example, the pores within silicon foams cannot be finely tuned and must be of a constant density. Even then, structural strength can be inconsistent.

But, fear not, 3D-printing may yet again come to the rescue… Researchers at a US national laboratory are developing additive manufacturing systems that can create energy-absorbing materials with features controlled on sub-micrometre scales. This precise tailoring will enable energy-absorption effectiveness to be tuned precisely for specific applications. As a bonus, this process uses curable siloxane-resin base materials, which are more flexible than silicone foams and leave no residual catalyst during manufacturing. Collaborators in industry are sought for further development and licensing.

Hit the brakes and read the full article on IN-PART.

Follow the links to the other articles published in the IN-FOCUS: Nanotechnology series:

– The Difficult Promises of Graphene (Nokia Bell Labs)

– Nanotechnology & IP: Trends and Best Practices (Stratagem IPM)

– How Big Data & Machine Learning are Changing Materials Discovery (LLNL)

Wondering how nanoscale innovations developed through university researched are commercialized into new technologies? Check out some of our latest case studies to learn about industry-academia collaborations advancing this field:

– University of Cambridge: Evaluating New Carbon Nanomaterials with Proof-of-Concept Testing

– George Washington University: Graphene-Based Antimicrobial Coating Sent to Industry Partner for Testing

Technology features written by Charlotte, Dan Judd, Joanna, Emma, Josh, Alicja.

Edited & Produced by Alex.

Links updated September 2018.

Copyrights reserved unless otherwise agreed – IN-PART Publishing Ltd. 2018

The information about the technologies presented within this feature is derived from ‘technology overviews’ provided contributing universities. We endeavour to maintain scientific integrity. We strive to ensure that the information we present is as accurate and up-to-date as possible; however, mistakes do occasionally occur. If you spot a mistake, please let us know.

Image attribution (in order of appearance):

Dennis van Zuijlekom / Flickr (CC BY-SA 2.0)

The3cats / Pixabay (CC0)

Richard Ortega / Unsplash (CC0)

Jesse Wagstaff / Flickr (CC BY 2.0)

Cory Schadt / Unsplash (CC0)

Billy Huynh / Unsplash (CC0)

Broken Inaglory (CC BY 3.0)

Meharris / Wikimedia (CC BY 3.0)

Luke Jones / Flickr (CC BY 2.0)

About IN-PART:

We believe brilliant connections can solve real-world problems. We match research pioneers from academia with decision-makers in industry sectors striving for a greater positive impact.

Our goal is to enable connections from around the world to match academic research with industry on a level playing field. Through our intelligent, matchmaking platform we showcase leading university innovations and connect academics with an international community of decision-makers in industry, creating meaningful dialogue and partnership.

IN-PART, a digital partnering platform for university-industry collaboration.

250+ universities and research institutes around the world currently showcase their research and innovation on IN-PART to find new collaboration partners in industry. R&D teams get free access to the platform (create a free account here). There are no hidden costs and we don’t claim downstream success fees.

Discover, a bespoke scouting service for open innovation.

Through Discover, corporate R&D teams can leverage our extended academic network, which reaches multiple teams across 1,200+ universities and research institutes worldwide. In response to a specific research requirement or challenge, Discover enables R&D teams to identify new opportunities for commercialisation or to solicit proposals for new research.

Interested in speaking with our Discover team? Request a demo | TTO or academic? Sign-up for weekly Discover emails.